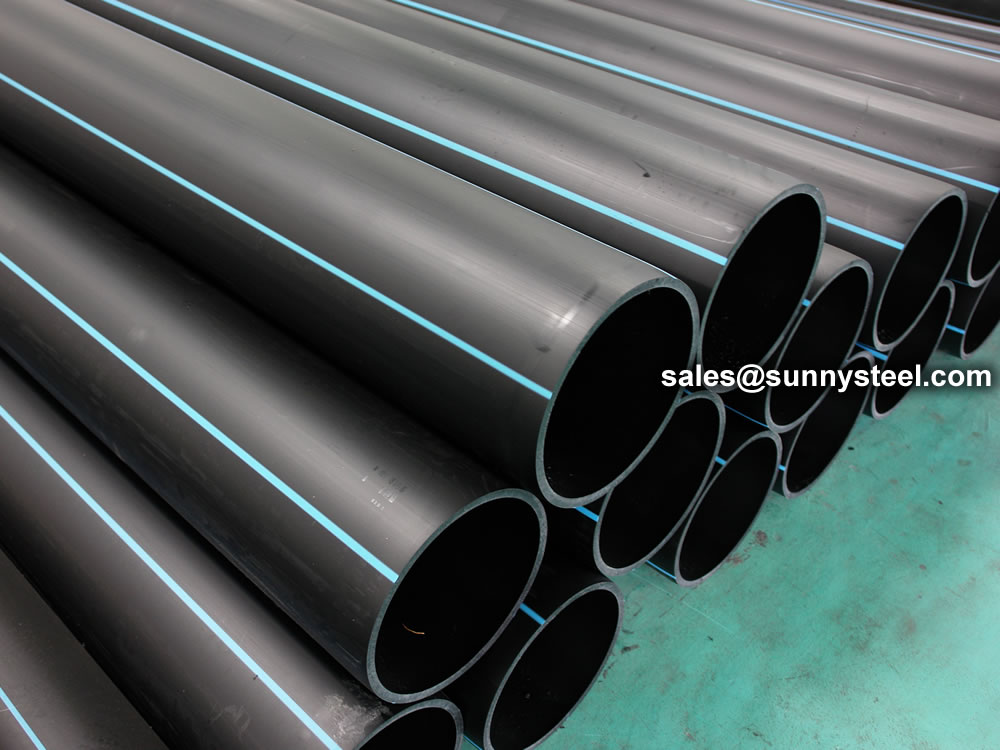

Check Out the Production Process Behind High-Quality HDPE Pipe and Its Applications

The production procedure of top notch HDPE pipes is elaborate and methodical. It begins with the choice of resources that improve efficiency. Following this, ethylene undertakes polymerization to create material, which is then formed with extrusion. Quality assurance is extremely important, making certain that the last item fulfills strict standards. The journey of HDPE pipes doesn't finish with production. Their applications throughout numerous industries disclose a more comprehensive significance worth examining.

Comprehending HDPE: Residences and Advantages

High-density polyethylene (HDPE) is a flexible thermoplastic known for its toughness and resistance to different ecological factors. This product displays exceptional tensile toughness, making it ideal for demanding applications. Its low-density framework contributes to a light-weight product, promoting ease of handling and installation. HDPE additionally showcases remarkable resistance to chemicals, which reduces destruction when exposed to harsh substances.

The product's low wetness absorption additionally improves its durability, making it perfect for usage in pipes and storage containers. Additionally, HDPE is resistant to ultraviolet (UV) radiation, guaranteeing that products keep their integrity also when exposed to sunshine. Its versatility permits for the development of elaborate shapes without endangering stamina. The environmentally friendly nature of HDPE, usually stemmed from recycled materials, adds to its charm, promoting lasting techniques in production. Overall, these properties and advantages make HDPE a preferred choice for various commercial and customer applications.

Basic Material Option for HDPE Manufacturing

The option of resources for HDPE manufacturing is vital to verify the end product meets the preferred specifications and high quality requirements. High-density polyethylene (HDPE) is largely created from polymerized ethylene, originated from nonrenewable fuel sources such as gas or unrefined oil. The top quality of these feedstocks greatly affects the mechanical and thermal residential properties of the final HDPE.

Additives also play a substantial role in boosting HDPE's performance, consisting of antioxidants, UV stabilizers, and colorants, which enhance resilience and resistance to ecological aspects. The choice process have to take into consideration not only the chemical composition of the raw products however likewise their processing features to ensure effective production.

Furthermore, the sourcing of resources ought to prioritize sustainability and compliance with environmental guidelines, as accountable methods are crucial in today's market. Ultimately, cautious basic material choice lays the structure for creating top notch HDPE pipes suitable for diverse applications.

The Extrusion Refine: Shaping HDPE Pipeline

The extrusion process plays an important duty fit HDPE pipelines, beginning with meticulous material prep work methods that assure optimal flow and consistency. Equally vital is the style of the die, which directly affects the final measurements and surface high quality of the pipe. Together, these aspects add considerably to the efficiency and high quality of HDPE pipe production.

Material Prep Work Strategies

Efficient production of HDPE pipes begins with careful product prep work methods, specifically the extrusion process. Throughout this stage, high-density polyethylene material is initial dried to get rid of moisture, ensuring optimal flow attributes. The resin is then fed right into the extruder, where it undergoes heating and melting, changing into a thick state. This home heating procedure is meticulously regulated to maintain the material's integrity and efficiency. The molten HDPE is compelled with a die, forming it right into a continual pipeline form. Appropriate temperature administration throughout extrusion is vital, as it directly impacts the material's properties and the end product high quality. Once shaped, the HDPE pipe is cooled down and reduced to defined lengths, all set for succeeding handling and applications.

Die Design Importance

Precision in die style plays a necessary function in the extrusion process of HDPE pipelines. The die functions as the final shaping device, directly influencing the pipe's measurements, wall surface density, and surface area coating. A properly designed die warranties consistent material circulation, decreasing flaws such as abnormalities and vulnerable points. The geometry of the die must be maximized to fit the particular residential or commercial properties of HDPE, including its viscosity and thermal actions during extrusion. Additionally, the cooling price of the material as it travels through the die can substantially influence the pipeline's architectural honesty. Investing in innovative die technology is crucial for manufacturers intending to generate premium HDPE pipelines that meet market criteria and client assumptions.

High Quality Control Measures in HDPE Production

Numerous variables affect the high quality of HDPE pipe manufacturing, reliable top quality control steps are essential to assure consistency and reliability in the final product (Texas hdpe pipe manufacturer). Secret high quality control techniques consist of strenuous product evaluation, verifying that the raw polyethylene satisfies established criteria for pureness and thickness. Throughout the extrusion procedure, parameters such as temperature, pressure, and cooling time are carefully monitored to maintain dimensional accuracy and structural stability

Furthermore, post-production testing is crucial; read more manufacturers typically conduct hydrostatic tests to examine the pipeline's toughness and resistance to pressure. Aesthetic examinations for surface area problems even more enhance quality assurance. Accreditation from appropriate requirements companies, like ASTM or ISO, provides an additional layer of credibility. By executing these complete high quality control procedures, suppliers can minimize problems, improve efficiency, and guarantee that the HDPE pipelines fulfill the particular requirements of different applications, ultimately leading to client fulfillment and count on the product.

Applications of HDPE Pipeline Throughout Industries

HDPE pipes are used across various fields because of their toughness and versatility. In water distribution systems, they guarantee efficient shipment, while in wastewater management, they supply reputable services for waste transportation. Additionally, agricultural irrigation networks benefit from HDPE's resistance to deterioration and flexibility, making it an optimal selection for modern farming methods.

Water Distribution Systems

A significant variety of industries depend on high-density polyethylene (HDPE) pipes for effective water circulation systems. Recognized for their durability and resistance to deterioration, HDPE pipelines are widely utilized in municipal water networks, agricultural watering, and commercial applications. Their light-weight nature facilitates easy handling and installation, decreasing labor costs and time. Furthermore, HDPE pipes can fit different pressure levels, making them appropriate for both reduced and high-pressure systems. hdpe pipe suppliers Midland TX. The flexibility of the product enables seamless integration into existing facilities, decreasing the need for comprehensive excavation. HDPE's resistance to chemical leaching assurances that the water delivered continues to be risk-free and clean, making it an excellent option for maintaining the quality of drinkable water throughout various fields.

Wastewater Management Solutions

Reliable water distribution systems likewise lead the means for ingenious wastewater management options, where high-density polyethylene (HDPE) pipes play a substantial function. Popular for their sturdiness and resistance to rust, HDPE pipelines are suitable for transferring wastewater in different setups. Their adaptability permits simple setup in intricate settings, minimizing the need for extensive excavation. Additionally, HDPE's smooth interior surface decreases friction, enhancing flow prices and performance. These pipelines are also immune to chemical leaching, guaranteeing that impurities do not endanger the surrounding atmosphere. Industries, municipalities, and therapy centers significantly rely on HDPE pipelines for their integrity and durability, making them a recommended option for contemporary wastewater management systems. This versatility emphasizes the vital importance of HDPE pipes throughout various applications.

Agricultural Irrigation Networks

Agricultural watering networks benefit greatly from making use of high-density polyethylene (HDPE) pipes, which give reliable and dependable water delivery to plants. HDPE pipes are lightweight, making them very easy to transfer and set up, while their adaptability enables various setups in diverse surfaces. These pipelines show exceptional resistance to rust, chemicals, and UV radiation, making certain sturdiness in extreme agricultural environments. Additionally, their smooth interior surface lessens rubbing loss, enhancing water circulation and lowering power expenses connected with pumping. The long life of HDPE pipes, commonly exceeding half a century, adds to reduce maintenance and replacement costs. Farmers progressively depend on HDPE pipelines to improve watering efficiency and promote lasting farming techniques, eventually leading to improved crop yields and source preservation.

Future Fads in HDPE Pipeline Innovation

As the demand for lasting and reliable facilities expands, improvements in HDPE pipe innovation are poised to change different sectors. Arising trends include the assimilation of clever modern technologies, such as sensing units and IoT capabilities, which facilitate real-time monitoring of pipeline conditions, lowering maintenance prices and preventing leakages. Additionally, the development of sophisticated production strategies, such as 3D printing, is enabling the manufacturing of complex, tailored pipe layouts that satisfy specific job demands.

Moreover, the concentrate on recycling and circular economy practices is driving the technology of HDPE pipelines made from recycled products, enhancing sustainability. Improved jointing methods, such as electro-fusion and mechanical fittings, are also improving setup effectiveness and reliability. The growing emphasis on environmental laws is pushing makers to adopt greener manufacturing procedures, ensuring that HDPE pipes not only satisfy industry criteria yet additionally foster a more sustainable future for framework advancement.

Often Asked Concerns

Exactly How Does HDPE Compare to Other Plastic Products?

HDPE outshines many other plastic materials pertaining to longevity, chemical resistance, and versatility. Its low density and high tensile strength make it excellent for various applications, frequently exceeding choices in both efficiency and longevity.

What Are the Environmental Effects of HDPE Production?

The ecological influences of HDPE manufacturing include greenhouse gas exhausts, power consumption, and possible contamination from producing procedures. Additionally, improper disposal can cause dirt and water contamination, raising concerns concerning long-lasting ecological effects.

Can HDPE Pipeline Be Reused?

Yes, HDPE pipelines can be reused. Several centers approve used HDPE for processing, transforming it right into new products. This recycling contributes to sustainability initiatives, minimizing plastic waste while preserving resources and power in the production cycle.

What Is the Lifespan of HDPE Pipes?

Exactly How Do Temperature Level Variations Impact HDPE Pipeline Efficiency?

Temperature level variants significantly affect HDPE pipe efficiency, influencing flexibility and stamina. Heats can result in softening, while reduced temperatures might create brittleness, eventually affecting the pipeline's sturdiness and suitability for numerous applications in varied environments.